Metal Additive Manufacturing Equipment

Aconity MINI Metal Laser Powder Bed Fusion Printer (LPBF)

- Build space: Ø 140 mm x H 190 mm or Ø 55 mm x H 190 mm

- Laser Configuration: Single Mode 400 W

- Spot size for 3D Scanning: 80 – 500 μm

- Layer thickness: Down to 10 µm

- Max scan speed: 12 m/s

- Inert gas type / pressure: Argon 6 bar, Vacuum < 2 mbar

- Residual oxygen content: < 100 ppm

- Pressurized air / pressure: ISO 8573-1:2010 [1:4:1] / 6 bar

- Machine Dimensions (W x D X H): 2450 mm x 1500 mm x 2320 mm

- Machine weight w/o powder: 850 kg

- Product webpage: https://aconity3d.com/products/aconity-mini/

Tiger-Vac EXP1-20DT Powder Recovery System

- Powder Recovery System for Additive Manufacturing

- Meets NFPA 484 for Additive Manufacturing

paragraph 13.4.1 – Equipment listed for Class II, Group E atmospheres

- Meets NFPA 484 for Powder and Dust Collection

paragraph 11.2.4.4.1 – Cyclone without filter media

- Product webpage: https://www.tiger-vac.com/product.aspx?itID=1132

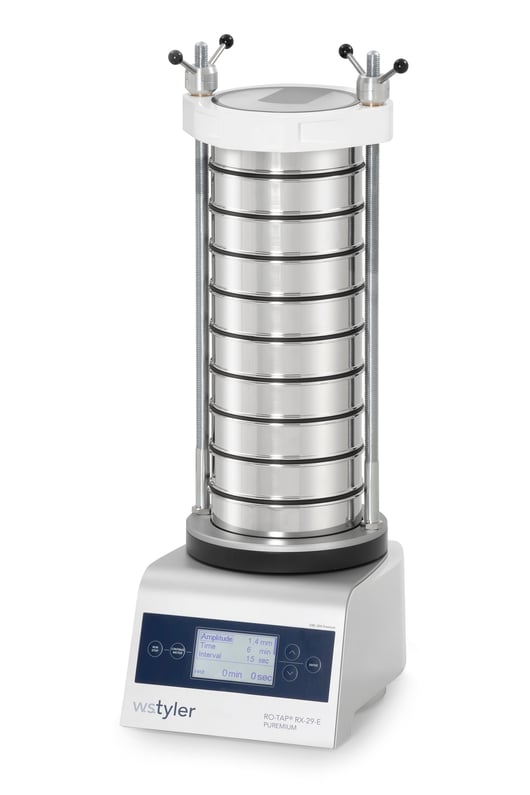

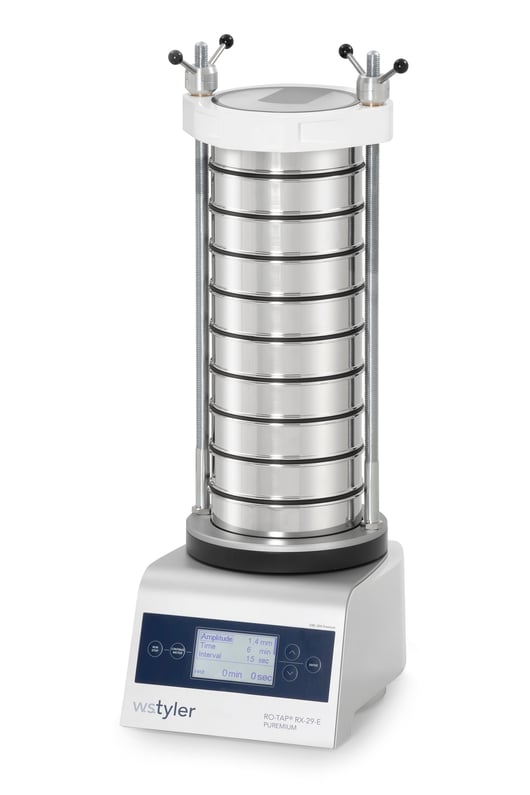

W.S.Tyler RX-30-E Powder Dry Sieving System

- The Sieve Shaker operates with 12" diameter Test Sieves and offers precise sieving results.

- Product webpage: https://wstyler.com/particle-analysis/ro-tap-sieve-shaker/rx-29-e-and-rx-30-e-premium-sieve-shaker

Bench Top Sand Blaster

- Ideal surface treatment

- Air compressor delivery of 40-120PSI @ 15-25CFM

- 4 extra nozzle (4/5/6/7mm) and large gloves

- Removable mesh-design work surface tray

- Drain plug for easy cleaning

- Oversized viewing rubber glass with built-in LED tube for better visibility

Metrology Equipment

PrintRite3D Co-Axial Meltpool Monitoring System

- Sigma's interative system combines inspection, feedback, data collection, and critical data analysis for management of LPBF processes. It includes three coaxial photodiode sensors to measure meltpool radiated emissivity and temperature at 100 micron resolution.

Olympus BX61 Fully Motorized Metallurgical Microscope

- Motorized stage for automatic stitching for measuring large area

- Olympus laser based autofocis

- Objective lens: 10x/0.3

- Lens: 20x, 50x, 100x

- 25MP high-resolution camera

- Product webpage: https://www.olympus-ims.com/en/microscope/bx61-2/

Filmetrics Profilm3D Optical Profilometrer

- White light interferometry-based (WLI) 3D surface topography measurement system

- Motorized stage for automatic stitching

- Mininum axial resolution: 0.92um with 10x objective lens

- Product webpage: https://www.kla.com/products/instruments/optical-profilers/profilm3d

Sensors and Data Acquisition System

Acoustic Emission Sensors, Vibration Sensors, Hydrophone Sensors, Pre Amplifier for Sensors, IDK-AET-SU8 with 8-Channel 10MHz Data Acquisition System, IDK AE Software, NI Data Acquisition Systems

3D Printing Equipment

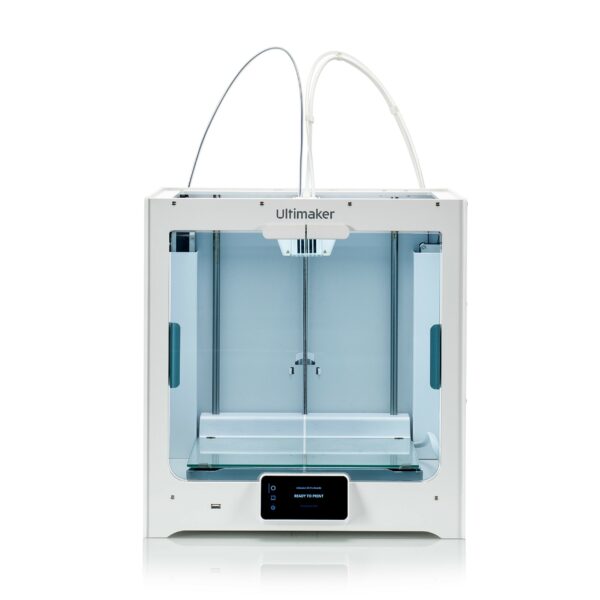

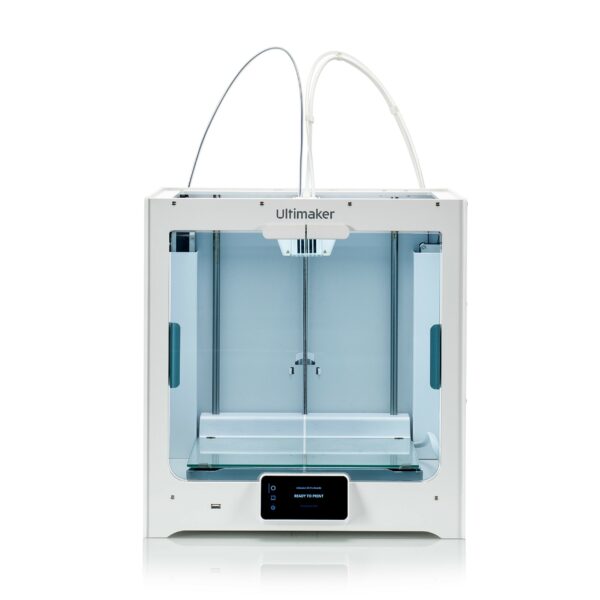

Ultimaker S3 3D printer

- Print technology: Fused Deposition Modeling (FDM)

- Build volume: 230 x 190 x 200 mm (9 x 7.4 x 7.9 inches)

- Layer resolution: 600-20um

- XYZ resolution: 6.9, 6.9, 2.5 micron

- Feeder type: Dual-geared feeder, reinforced for composite materials

- Build speed: < 24 mm³/s

- Nozzle temperature: 180 - 280 °C

- Product webpage: https://ultimaker.com/3d-printers/s-series/ultimaker-s3/

Snapmaker 2.0 3D printer

- Print technology: Fused Deposition Modeling (FDM)

- Build volume: 12.6 x 13 x 13.8" / 32.0 x 33 x 35.1 cm

- Layer resolution: 50 to 300 micron / 0.05 to 0.3 mm

- Nozzle temperature: 527°F / 275°C

- Build Plate Temperature: 176°F / 80°C

- Filament Compatibility: ABS, PLA, TPU, Wood

- Laser Engraving and CNC Carving capabilities

- Product webpage: https://us.snapmaker.com/products/snapmaker-2-0-modular-3-in-1-3d-printer-a350t-a250t

Computing Equipment

- Intel i9 Tower Workstation with Triple Nvidia RTX A5000

- Intel Xeon Workstation with NVIDIA GPU

- Five Dell workstation computers